In the pyrometallurgical production of antimony ore, the rotary furnace is the key equipment for producing antimony products such as antimony trioxide, and its role in multiple core links is irreplaceable.

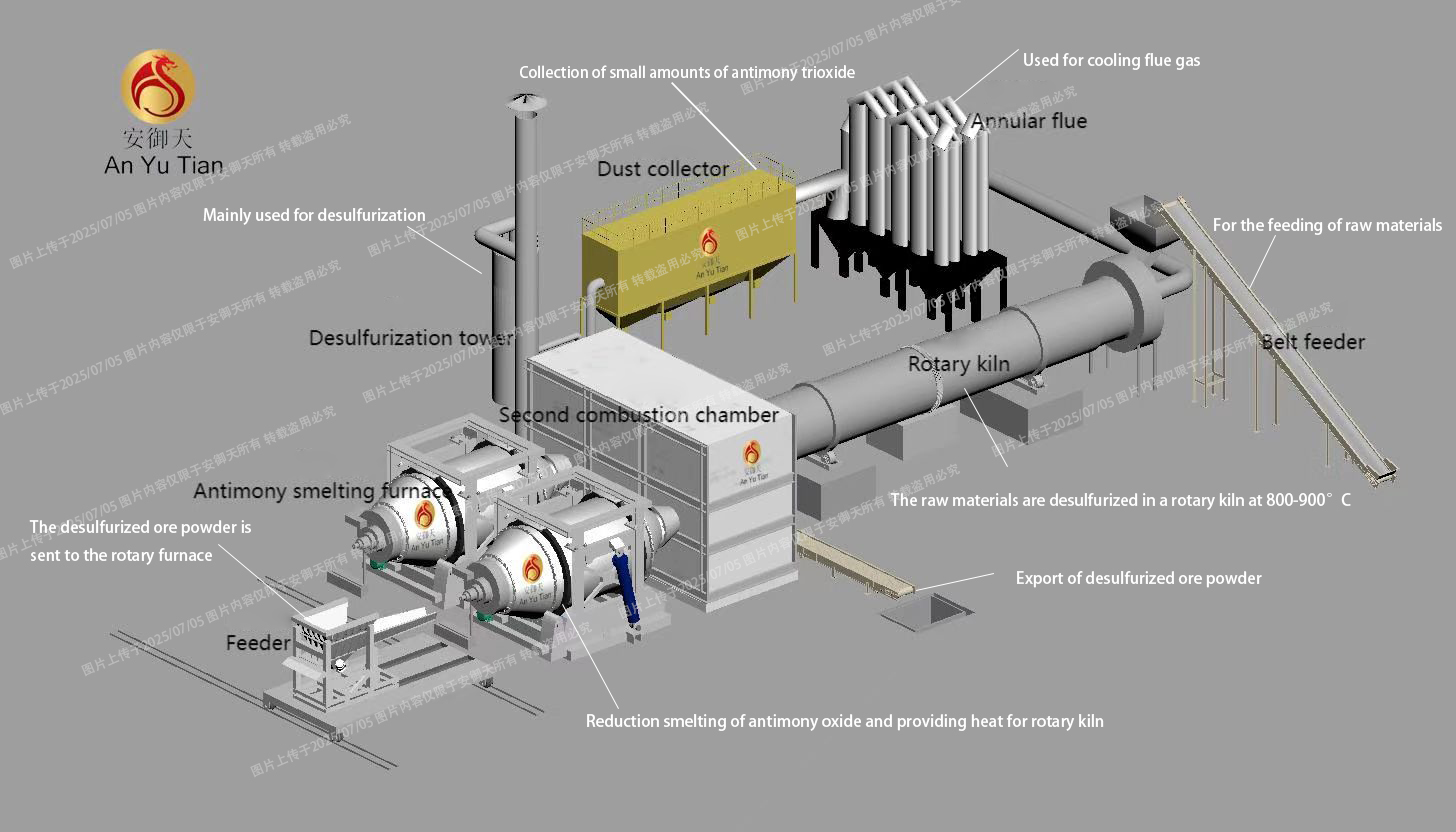

At the beginning of the process, the belt feeder steadily and continuously transports the antimony ore to the rotary kiln, where it is roasted and desulfurized at a high temperature of 800-900℃. The desulfurized ore powder is accurately fed into the rotary kiln by the feeder.

The rotary kiln is the core hub of the processing flow. In the antimony oxide reduction smelting link, the ore powder undergoes complex reactions under a specific high temperature and reducing atmosphere to produce crude antimony metal. At the same time, it transfers excess heat to the rotary kiln through efficient heat exchange, realizing energy recycling, improving energy efficiency and reducing consumption.

The high-temperature flue gas generated by smelting first enters the annular flue for preliminary cooling, and then flows through the dust collector to recover a small amount of valuable antimony trioxide to avoid waste. Finally, it enters the desulfurization tower for purification to ensure that the emission meets the standards.

To obtain refined antimony or antimony trioxide products, subsequent processes are required. When refining crude antimony, it is added to the refining furnace with refining agent for high-temperature refining to remove impurities and obtain pure antimony liquid. If antimony ingots are produced, the antimony liquid enters the continuous casting machine, and after forming, it is grabbed, stacked, bundled and packaged by the manipulator stacking machine; if antimony oxide powder is produced, the antimony liquid is further oxidized in the refining furnace (oxidation furnace) to form antimony trioxide, which volatilizes into the dust removal system and is collected in the dust collector.

From antimony ore to the final product, the rotary furnace runs through the whole process, not only in the key reduction smelting link, but also in coordination with other equipment to ensure efficient and environmentally friendly operation of the process, providing a solid material foundation for the antimony industry.