The production process is precisely designed to convert ore into high-purity products, mainly covering two production routes: metallic antimony and antimony oxide powder (Sb2O3).

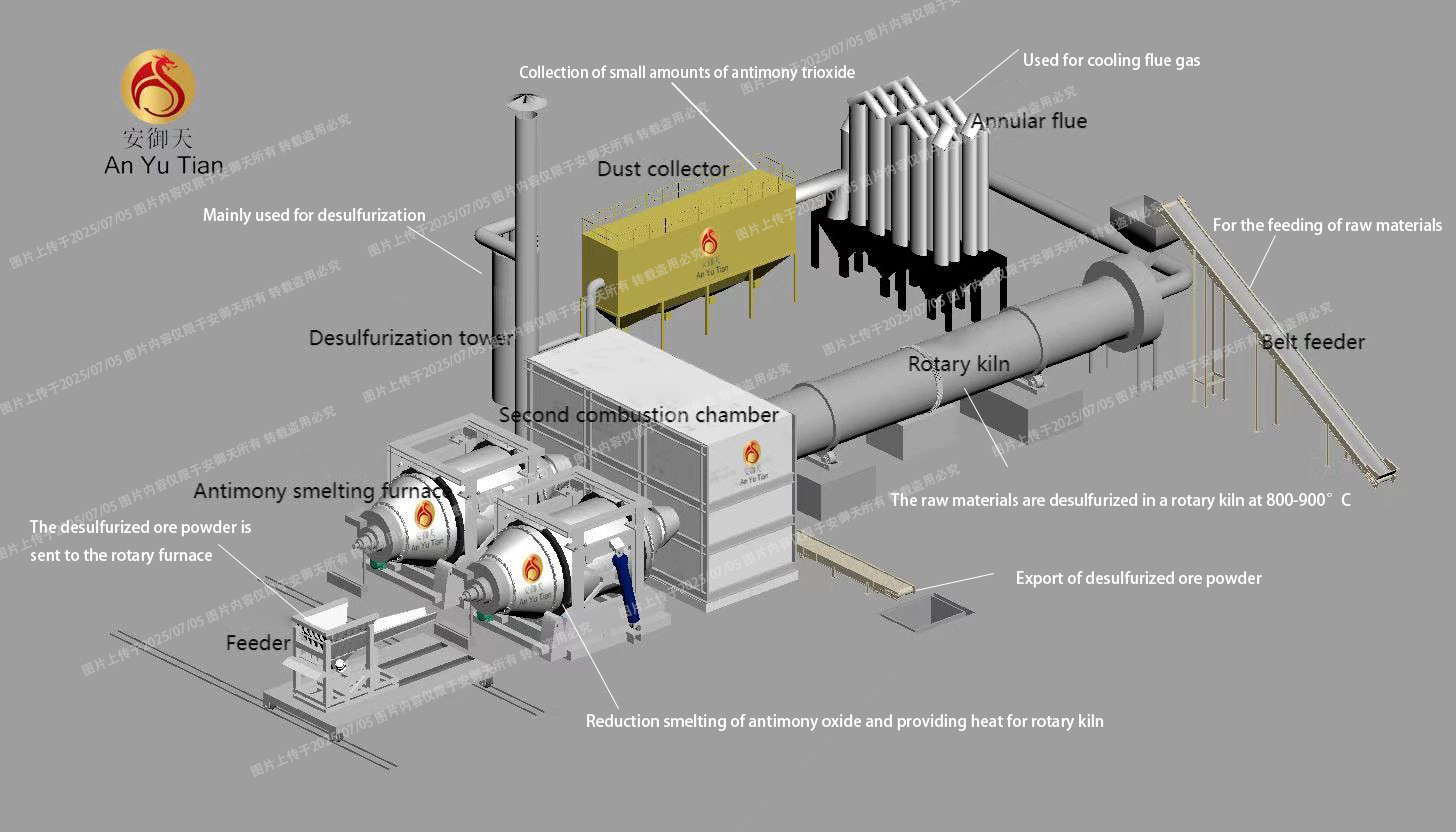

In the raw material processing stage, the antimony ore is first crushed to a suitable particle size by a crusher to create conditions for subsequent purification. After that, the crushed ore enters the rotary kiln and undergoes desulfurization treatment in a high-temperature environment to effectively remove impurities and initially enrich the antimony element.

The desulfurized antimony ore powder enters the high-temperature reduction smelting stage. A reducing agent is added to the antimony smelting rotary furnace, and at a high temperature of about 1200°C, antimony oxide is reduced to produce crude antimony. Because crude antimony contains impurities, it needs to be melted and cast into antimony anode plates and enter the electrolytic refining stage. In the electrolytic cell, the antimony anode plate is used as the anode, and the power is turned on under a specific electrolyte system. High-purity antimony is precipitated at the cathode to form cathode antimony, which is then made into high-purity antimony ingots through a melting and casting process.

When producing antimony oxide powder (Sb2O3), the antimony cathode plate after electrolysis needs to be oxidized and volatilized. At a specific temperature, metallic antimony reacts with oxygen to generate antimony oxide gas, which is collected by the cooling system to obtain white antimony oxide powder (Sb2O3). This product is widely used in the plastics, rubber and textile industries as a high-efficiency flame retardant.

The entire process achieves efficient resource conversion and effective pollution control through equipment linkage and energy cascade utilization. The combination of high-temperature desulfurization and reduction smelting technology not only ensures product quality, but also meets environmental protection requirements, fully demonstrating the technological progress of modern metallurgical processes.