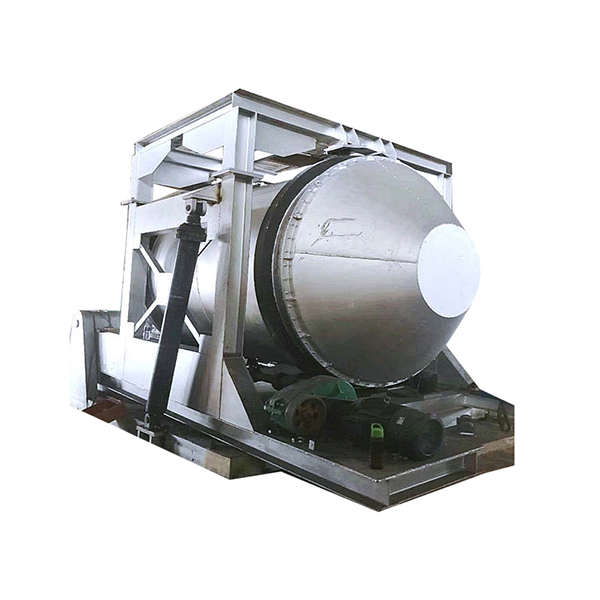

As an important equipment in the aluminum smelting industry, the aluminum melting rotary furnace provides a strong guarantee for the production of aluminum products with its efficient and stable operation mode. From the preparation before starting to smelting, separation, slag removal, refining, and operation monitoring and maintenance, every link is crucial.

Before starting the aluminum melting rotary furnace, sufficient preparation is the basis for ensuring the smooth operation of the equipment. Check whether the pushing device, circulating water, air pressure, etc. are normal, and whether the position of the limit switch and manual automatic switch is accurate. These seemingly simple steps are actually related to the safety and stability of the equipment. At the same time, the materials on the workbench are strictly screened to ensure that they meet the forging requirements, laying a solid foundation for the subsequent smelting process.

As the furnace door slowly opens, the aluminum material is loaded into the aluminum melting rotary furnace in an orderly manner. In the preheating stage, cold furnace combustion requires special care to avoid cracks in the furnace lining due to rapid heating. When the temperature of the furnace lining reaches the appropriate range evenly, the smelting process officially begins. The flame jumps in the furnace, transferring heat to the aluminum material, causing it to gradually melt. At this time, the addition of alloying elements adds new characteristics to the aluminum melt, making its composition more in line with production requirements.

After smelting is completed, the separation of aluminum ash and aluminum becomes a key step. The aluminum melting rotary furnace uses the centrifugal force generated by high-speed rotation to effectively separate the aluminum and aluminum ash in the mixture. This technology not only improves the recovery rate of aluminum, but also reduces production costs. Subsequently, the slag removal operation follows to remove impurities such as oxides on the surface of the aluminum melt to ensure the purity of the aluminum product.

The refining process should not be ignored either. The aluminum melt is further treated in the insulation furnace to remove gases and inclusions in it and improve its purity and quality. All of this is inseparable from the escort of operation monitoring and maintenance. Real-time monitoring of the aluminum melting rotary furnace can timely discover and solve potential problems and ensure the long-term stable operation of the equipment.

The efficient operation and fine management of the aluminum melting rotary furnace not only improves the production efficiency and quality of aluminum products, but also injects new vitality into the sustainable development of the aluminum smelting industry. In the future development, the aluminum melting rotary furnace will continue to play its unique advantages and contribute more to the production of aluminum products.