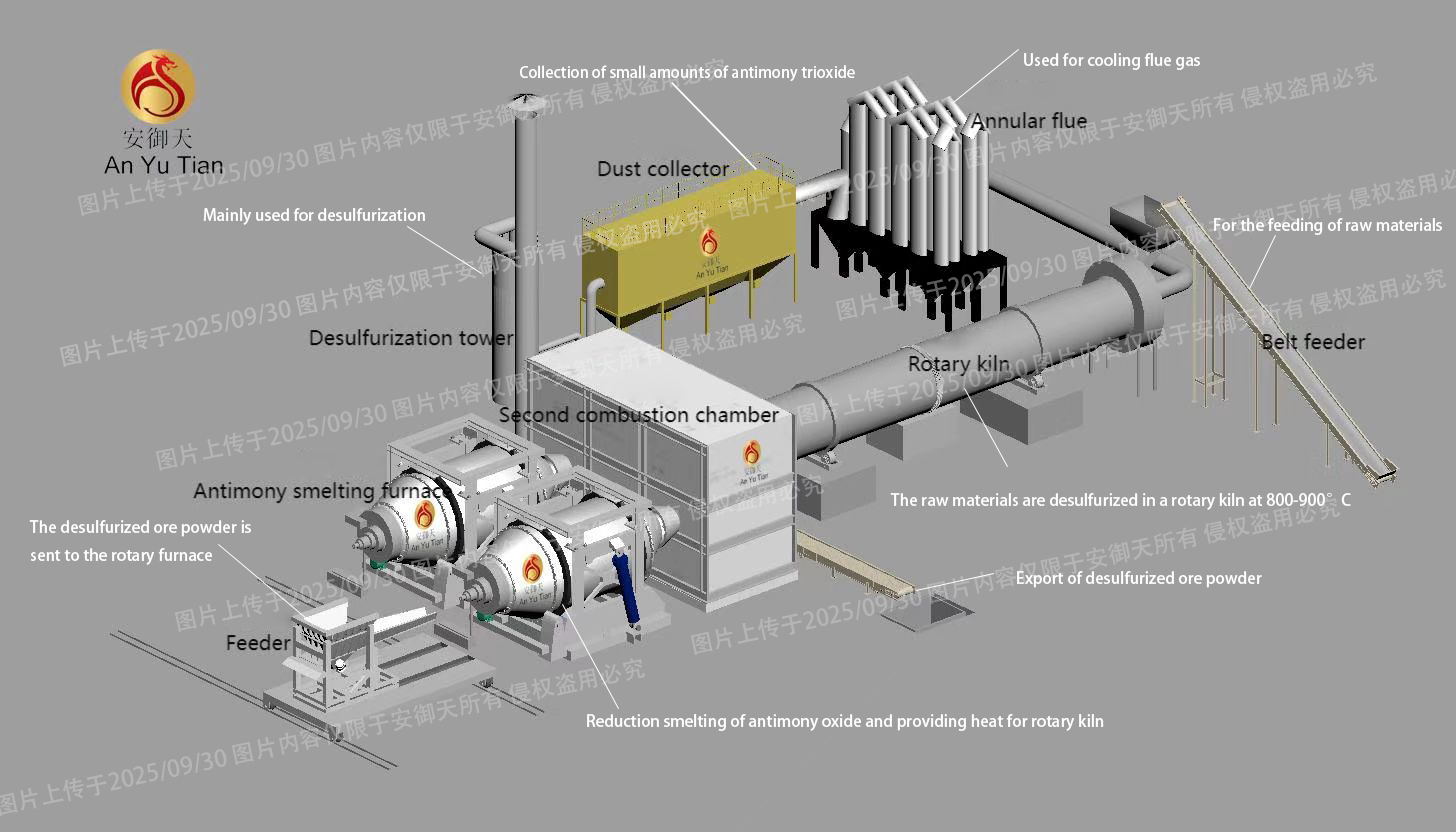

Antimony trioxide, as an important industrial raw material and flame retardant additive, relies on a precision designed and collaborative equipment system for efficient and clean production. From antimony ore to high-purity antimony oxide powder, the main equipment is connected in series, forming a complete process chain that integrates smelting, conversion, recovery, and environmental protection.

1. Pre treatment and desulfurization core: rotary kiln

The process begins with a rotary kiln, where antimony ore is fed into a long cylindrical rotary furnace through a belt feeder, and then roasted and desulfurized at a high temperature of 800-900 ℃ to convert it into desulfurized ore powder. Its continuous rotation ensures uniform heating and sufficient desulfurization of the material, laying the raw material foundation for subsequent processes.

2. Metal Reduction and Energy Hub: Rotary Furnace

The desulfurized ore powder enters the rotary furnace through the feeder and is reduced to produce crude antimony metal at high temperature. The rotary furnace is not only the core of smelting, but also the "energy heart". Its high-temperature waste heat is used in the rotary kiln to achieve efficient energy circulation and reduce overall energy consumption.

3. Oxidation conversion and volatilization section: refining furnace/oxidation furnace

Crude antimony needs to be further converted into antimony trioxide. In the refining furnace (oxidation furnace), molten crude antimony comes into contact with air (or oxygen enriched air) for oxidation, generating gaseous antimony trioxide. The furnace design ensures sufficient reaction and effective volatilization of products into the flue gas system.

4. Key to product collection: dust removal system

The high-temperature antimony trioxide gas enters the dust collector (such as a bag filter) after being initially cooled by the flue gas through the annular flue, which is the core process of product recovery. When dusty flue gas passes through, antimony trioxide powder is captured, separated, and deposited to obtain the final product. The system efficiency affects the recovery rate and economic benefits.

5. Environmental protection terminal: desulfurization tower

After recycling antimony trioxide, the flue gas needs to be purified. The desulfurization tower is a terminal environmental protection equipment. The flue gas is subjected to desulfurization processes such as alkaline washing to remove harmful gases such as sulfur dioxide, meet emission standards, and ensure green and sustainable production.

The production of antimony trioxide relies on the orderly connection and coordination of equipment such as rotary kilns, rotary furnaces, refining furnaces/oxidation furnaces, dust removal systems, and desulfurization towers. The role of the rotary furnace and dust collector is crucial. The entire system embodies the concept of efficient resource utilization, energy cascade recovery, and environmental control, ensuring stable and clean production of high-quality antimony trioxide.