In the complex process of antimony smelting, both rotary refining furnaces and rotary furnaces play an important role, but there are significant differences in their functions and applications.

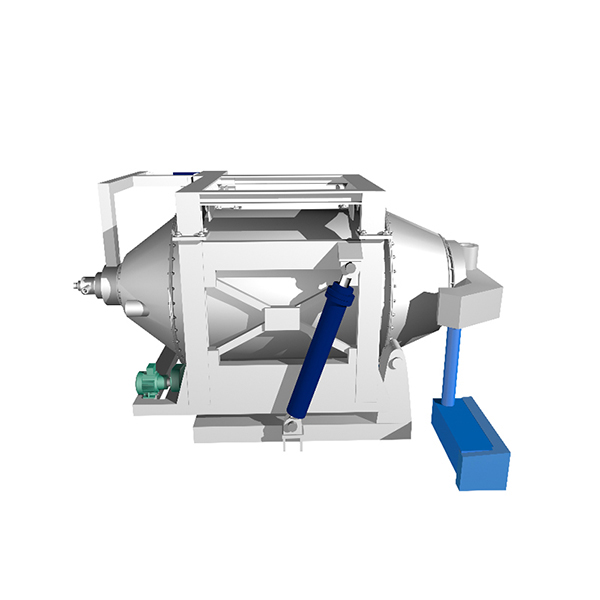

The rotary refining furnace can be regarded as the core key equipment for crude antimony purification in the antimony smelting process. Its core positioning is very clear, which is to deeply purify the crude antimony produced by reduction smelting. After this link, the crude antimony can be purified to the level of refined antimony, thereby meeting the quality standard requirements of commodity antimony on the market and ensuring that the product can smoothly enter the market for circulation and application.

The difference between the rotary furnace and the rotary refining furnace is reflected in many important aspects. First of all, in terms of core function, the main task of the rotary furnace is to reduce the ore powder into crude antimony through a series of reactions. The antimony content of this crude antimony is usually between 96% and 97%, and it also contains a certain amount of impurities. The rotary refining furnace focuses on the deep purification of the impure crude antimony produced by reduction smelting, and finally produces high-purity refined antimony with an antimony content of not less than 99.65%.

From the perspective of reaction type, the main reaction in the rotary furnace is reduction reaction. For example, under certain conditions, carbon is used as a reducing agent to reduce Sb2O3 to crude antimony. In contrast, an oxidation reaction is carried out in a rotary refining furnace. By introducing air into the furnace, the oxygen in the air is used to oxidize the impurity elements in the crude antimony, so that the impurities are separated from the antimony in the form of oxides.

In terms of the objects to be treated, the two are also significantly different. The rotary furnace treats antimony oxide (Sb2O3), which is a relatively front-end material in the antimony smelting process. The rotary refining furnace treats crude antimony after reduction smelting. At this time, the crude antimony already has a certain antimony content, but it does not meet the purity requirements of commercial antimony.

From the perspective of process position, the rotary furnace is in the middle link of the antimony smelting process. It undertakes the material processing at the front end and provides crude antimony raw materials for subsequent refining. The rotary refining furnace is the last refining link of the entire smelting process. After its treatment, the antimony product reaches the final purity requirement and can enter the subsequent processing or sales link.