In the electrolytic refining process of antimony, the rotary furnace casting process is crucial. It is the key link between the electrolysis link and the production of finished antimony ingots. Its technical characteristics play a decisive role in the purity and quality of the final product. This process uses the dynamic smelting and precise atmosphere control of the rotary furnace to achieve deep purification and structural densification of cathode antimony.

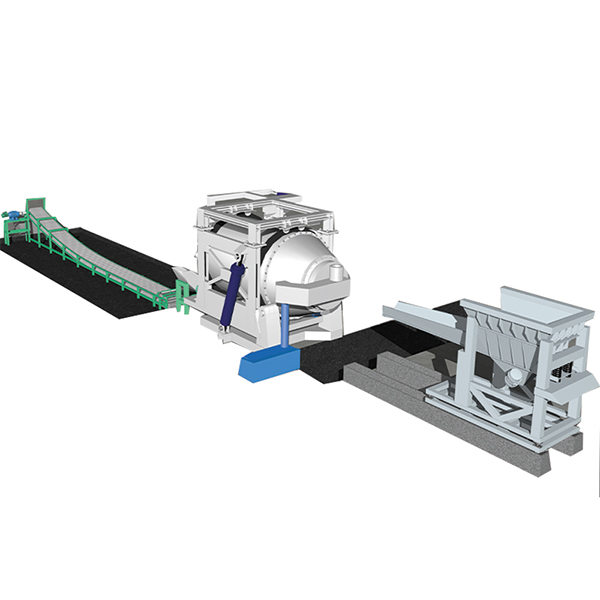

The cathode antimony plates produced by the electrolysis workshop are mechanically conveyed into the tilting rotary furnace. Under strictly controlled temperature conditions, solid antimony quickly melts into a silver-bright melt with good fluidity. This melting stage is not only a transformation of form, but also the final check on the quality of antimony. The purified antimony melt needs to be strictly insulated to maintain optimal fluidity. At this time, the tilting function of the rotary furnace is very useful, and the operator or automatic control system can accurately control the tilt angle of the furnace body.

The antimony melt is smoothly and continuously injected into the preheated cast iron mold through the furnace nozzle or casting trough. Design factors such as mold size, taper, surface finish, etc. directly affect the appearance quality, demolding difficulty and internal crystal structure of the antimony ingot. During the casting process, speed and temperature control are the key points, the purpose is to avoid turbulent air entrainment, reduce oxidation, and ensure that the solidified ingot is dense and has no shrinkage holes.

The molten antimony is naturally cooled and solidified in the mold. After it is completely solidified and drops to a safe temperature, the antimony ingot is removed from the mold. At this time, the antimony ingot usually needs to be cleaned on the surface to remove flash, burrs, residual slag, etc., and then undergo strict weight and appearance inspections, and finally marked with furnace numbers, batch numbers, grades, etc., thus completing the entire melting and casting process.