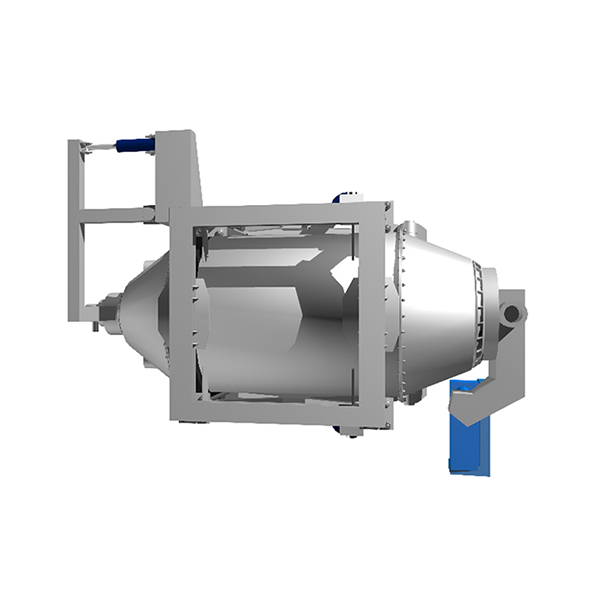

In the process of smelting antimony ore in a rotary furnace, local overheating of the cylinder is a common problem that needs attention. It may cause serious consequences such as equipment damage and production interruption. The main reasons for this phenomenon include the following aspects:

1. Lining peeling

The lining of the rotary furnace cylinder plays a key role in heat insulation and protection of the cylinder. Under long-term high temperature, material scouring and chemical erosion, the lining material will gradually age and wear. Once the lining peels off, the cylinder metal will be directly exposed to the high temperature environment. The thermal conductivity of metal is much higher than that of the lining material, and it will quickly absorb a large amount of heat, causing the local temperature to rise sharply, and then cause overheating.

2. Uneven distribution of materials

During the re-feeding process, if the feeding speed is unstable or the feeding position is improper, the material will be unevenly distributed in the cylinder. If there is too much material accumulation in some areas, the heat generated by the reaction cannot be dissipated in time, which will form a "hot spot" in this area, causing local overheating of the cylinder. Moreover, differences in material composition and particle size will also affect its heating and reaction conditions, further aggravating the problem of uneven material distribution.

3. Burner flame deviation

The uniform distribution of the burner flame is crucial to maintaining the temperature stability in the rotary furnace. If the burner is improperly installed, the air volume is not adjusted properly, or the fuel supply is uneven, the flame will be deflected, causing the heat to be concentrated in a local area of the cylinder. The temperature in this area rises rapidly, causing local overheating of the cylinder.

4. Cooling system failure

Insufficient cooling water flow, blockage of cooling pipes, or failure of cooling fans will lead to a decrease in cooling effect, and heat cannot be effectively dissipated, causing local overheating of the cylinder.

It can be seen that in the actual operation of the rotary furnace, it is necessary to pay close attention to these factors that may cause local overheating of the cylinder, and take effective measures to prevent and respond to them, so as to ensure that the rotary furnace can operate stably and efficiently, and ensure the smooth progress of antimony ore smelting production.