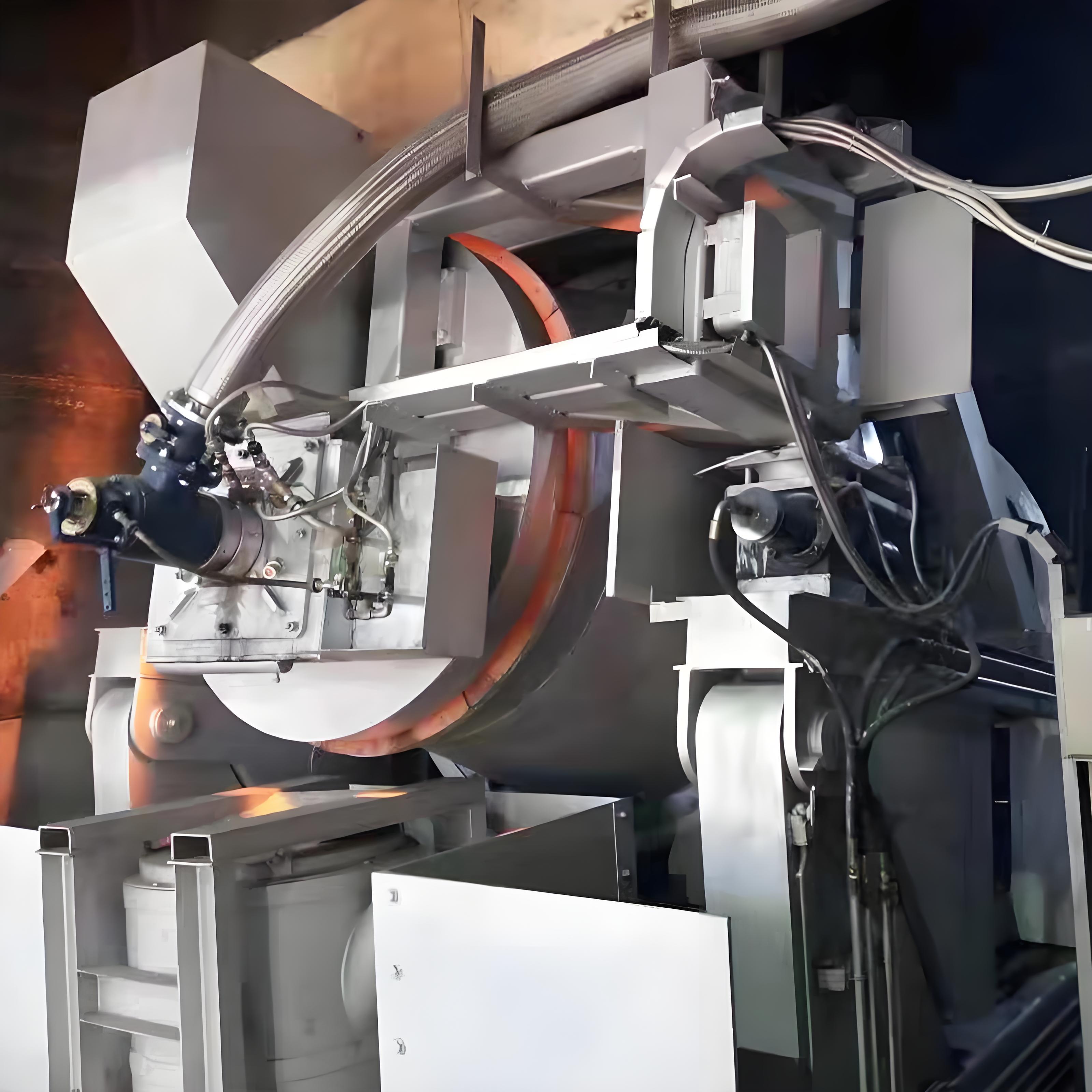

The antimony rotary furnace is the core equipment of the antimony smelting industry. It has significant advantages, especially its strong adaptability to raw materials and its ability to efficiently process a variety of antimony ores and antimony-containing materials.

Antimony sulfide ore (Sb?S?) is its main processing target, accounting for more than 70% of antimony resources, such as stibnite. In the rotary furnace, the antimony sulfide ore is volatilized and roasted, and oxidized at high temperature to generate volatile antimony trioxide (Sb?O?), which is then recovered by the condensation system.

Antimony oxide ore (Sb?O?) is treated by oxidation roasting-reduction smelting. After the antimony oxide ore is mixed with coke and preheated, it is oxidized at high temperature in the rotary furnace to generate antimony dioxide (SbO?), and then converted into metallic antimony through reduction reaction. It is suitable for antimony oxide minerals such as antimony ore and yellow antimony ore, especially ores with an oxidation rate of more than 50%.

For sulfur-oxygen mixed antimony ore, the rotary furnace can simultaneously process mixed ore of antimony sulfide and antimony oxide, without strict sorting, simplifying the process flow. By controlling the temperature and atmosphere in the furnace, efficient volatilization of antimony can be achieved, with a volatilization rate of more than 90%, and the quality of the antimony oxide powder produced is stable.

Low-grade antimony ore and smelting intermediate products can also be effectively processed by the rotary furnace. The rotary furnace is used to treat lean ore containing less than 5% antimony, and an antimony volatilization rate of 80% - 90% can be achieved through boiling roasting; the intermediate products such as antimony oxide powder and slag produced by blast furnace smelting can be returned to the rotary furnace for further processing to improve resource utilization.

Special composite antimony ores such as brittle sulfur antimony lead ore often coexist with metals such as lead and zinc. When processing, boiling roasting and sintering - blast furnace reduction smelting are combined, and the rotary furnace is responsible for the volatilization roasting link to achieve efficient separation of antimony and gangue.

The antimony rotary furnace has three major advantages: first, it is highly adaptable and can process sulfide ores, oxide ores, mixed ores and low-grade ores, covering a wide range of antimony oxidation rates from <30% to >50%; second, it has a high recovery rate. By optimizing the volatilization roasting and condensation process, the antimony recovery rate can reach 97% - 98%, and the antimony content in the kiln slag is low; third, it is environmentally friendly. Combined with the flue gas purification system, it can effectively control SO? emissions and meet environmental protection standards. In terms of application, it provides high-purity antimony oxide powder raw materials for the production of flame retardant materials, and also provides technical support for the production of sodium antimonate pyrochlore clarifiers for photovoltaic glass. In short, the antimony rotary furnace is an indispensable core equipment for the antimony smelting industry to process a variety of antimony ores.