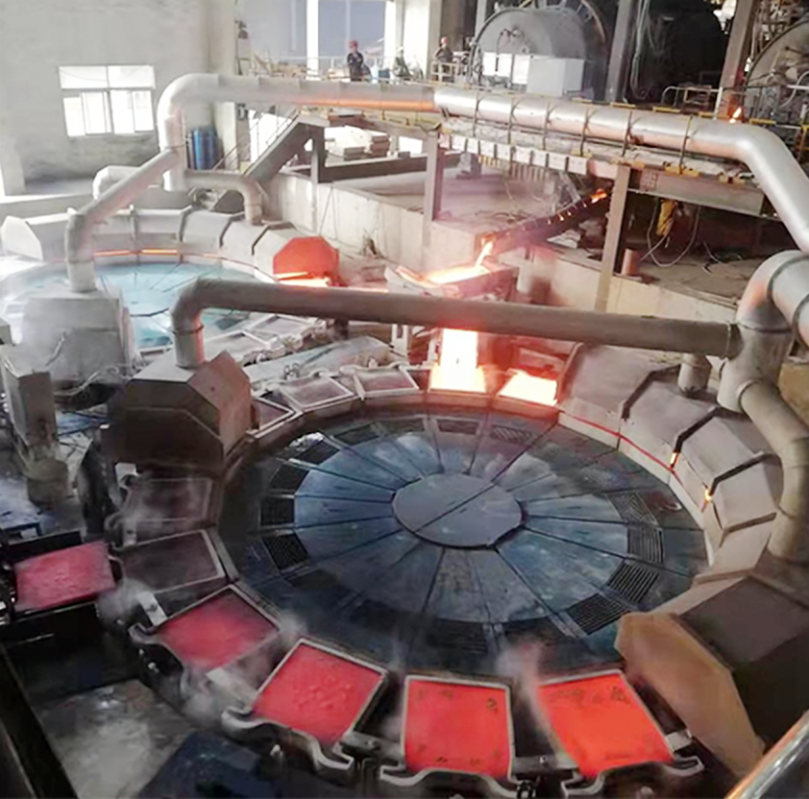

The electrolytic copper disc casting machine is a key equipment used in the copper smelting industry to cast molten electrolytic copper into anode plates or other shapes. Its technical performance directly affects production efficiency and product quality. The following is an analysis of some of its key technologies:

I. Mechanical structure and motion control

1. Disc rotation accuracy

The positioning accuracy and rotation stability of the casting disc are the core. High-precision servo drive or variable frequency speed regulation system is required to ensure that the mold station is accurately aligned with the casting port to avoid copper liquid splashing or uneven casting.

2. Mold layout and locking mechanism

The mold needs to be evenly distributed to balance the load, and the locking mechanism needs to be resistant to high temperature and open and close quickly to prevent copper liquid leakage. The mold design also needs to consider the convenience of demoulding and reduce copper sticking.

3. Multi-station collaboration

The disc needs to be synchronized with the ladle, cooling, demoulding, coding and other stations to optimize the beat time (such as controlling the single cycle time to 2-3 minutes) and improve production capacity.

2. Temperature control technology

1. Constant temperature casting of copper liquid

The temperature of copper liquid needs to be stable at 1130~1180℃ (adjusted according to copper purity). Electromagnetic heating or gas insulation furnace is used, combined with infrared temperature measurement feedback system to prevent pores and cracks caused by overcooling or overheating.

2. Mold preheating and cooling system

The mold needs to be preheated to 200~300℃ to reduce thermal stress. At the same time, water cooling or air cooling system is configured to ensure rapid and uniform cooling of the copper plate to avoid internal shrinkage or surface oxidation.

3. Inert gas protection

Nitrogen or argon is introduced during the casting process to reduce copper liquid oxidation and reduce the impurity content on the surface of the anode plate.

3. Automation and intelligent control

1.PLC/HMI integrated control

The programmable logic controller (PLC) and human-machine interface (HMI) are used to realize full process automation, including dynamic adjustment of parameters such as casting speed, disc speed, and cooling time.

2. Machine vision inspection

Deploy cameras and AI algorithms to monitor copper plate surface defects (such as cracks and pores) in real time, automatically remove unqualified products and adjust process parameters.

3. Data collection and optimization

Collect production data through industrial Internet of Things, optimize casting parameters with big data analysis, and predict mold life and equipment maintenance cycle.

The above is an analysis of some core technologies of electrolytic copper disc casting machines. Future development directions include a higher degree of digitalization and green manufacturing (zero-emission process) to meet the copper smelting industry's continued demand for high efficiency, energy saving and environmental protection.