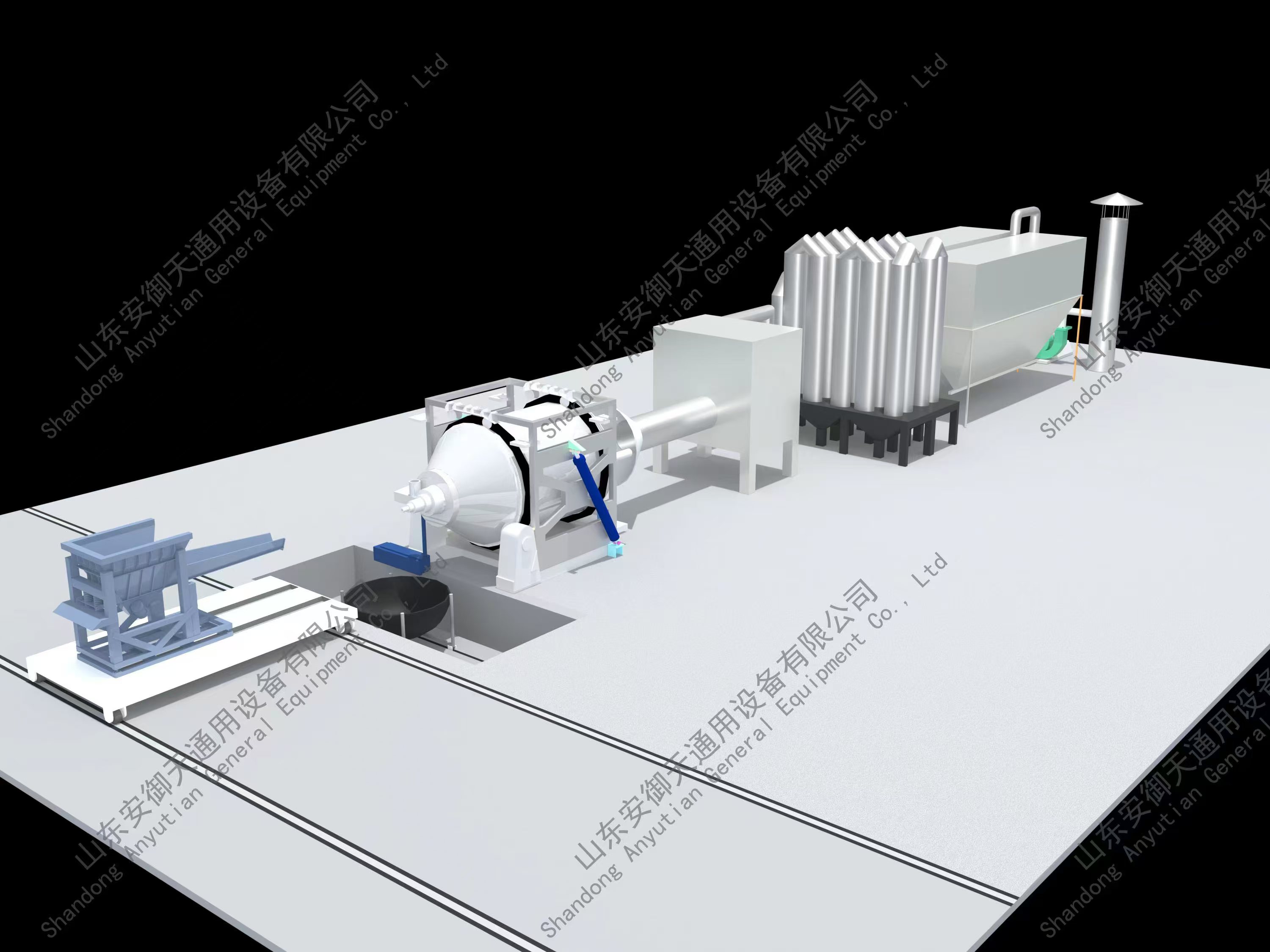

In addition to recycling waste batteries to smelt lead, extracting and refining lead from lead ore is also an important source of lead. The lead smelting process involves grinding, flotation, and furnace firing in a rotary furnace. The lead smelting process technology will be introduced in detail below.

1. Grinding. In order to subdivide it into smaller particles. This can increase the surface area and facilitate the subsequent process. Commonly used grinding equipment includes ball mills and vertical mills. 2. Flotation. Flotation is the process of separating useful minerals from impurities in ore. The principle of flotation is to suspend useful mineral particles in the flotation liquid and settle impurity particles at the bottom through physical and chemical methods. The flotation liquid is generally a mixture of water and various chemical reagents. 3. Furnace firing is one of the key links in the lead smelting process. The lead ore that has been ground and floated is sent to the furnace for heating treatment. Furnace firing is divided into two stages, namely drying and calcining. Drying is to remove moisture and volatile substances from the ore for further processing. Calcination is to remove sulfur and other chemicals from the ore to reduce the impact on subsequent processes. Commonly used furnace firing equipment includes rotary furnaces. 4. The stage of extracting refined lead. Refined lead refers to the lead with higher purity extracted from the raw materials during the refining process. There are many methods for extracting refined lead, and the commonly used methods include pyrometallurgy and hydrometallurgy. The pyrometallurgical method is to react the calcined lead ore with coke at high temperature to obtain refined lead through a reduction method. The wet method is to soak the ore in a chemical solution and obtain refined lead through a chemical reaction.

The raw materials for extracting refined lead can be effectively obtained by firing in a rotary furnace