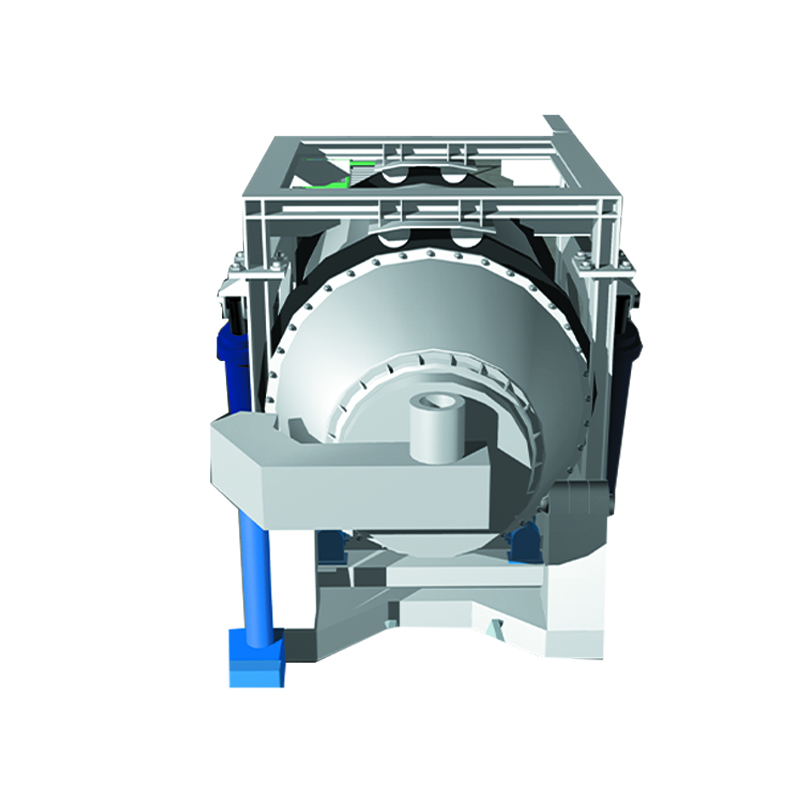

The smelting of lead concentrate in a rotary furnace requires processes such as crushing, sintering, smelting, and tail gas recovery.

1. Raw material preparation: First, the lead concentrate needs to be crushed into appropriate particle sizes for subsequent smelting treatment. At the same time, other auxiliary raw materials such as coke and limestone need to be prepared. 2. Raw material mixing: The crushed lead concentrate is mixed evenly with other auxiliary raw materials in a certain ratio to ensure that the subsequent smelting process can proceed smoothly. 3. Loading: Load the mixed raw materials into the converter, and add an appropriate amount of coke as a reducing agent to promote the reduction of lead oxides in the lead concentrate to metallic lead. 4. Heating: Start the converter heating system and heat the loaded converter to an appropriate temperature so that the metallic lead in the raw materials begins to melt and gradually separates. 5. Oxygen blowing: During the heating process, blow an appropriate amount of oxygen into the converter to oxidize other metal elements and impurities, so that they form oxides and are blown out of the converter. 6. Separation and collection: After oxygen is blown in, the metal lead will gradually separate and settle at the bottom of the converter. At this time, the metal lead can be separated from other impurities and collected by appropriate methods. 7. Cleaning and maintenance: After the smelting process, the converter needs to be cleaned and maintained to ensure that the next round of smelting can proceed smoothly. 8. Tail gas treatment: A large amount of tail gas will be generated during the smelting process, which may contain harmful gases and particulate matter, which needs to be reasonably treated and purified to protect the environment and personnel health.

After the above processes, the metal lead is smelted from the impurities by the rotary furnace and used in batteries, cable sheaths, machinery manufacturing, shipbuilding, light industry, lead oxide, radiation protection and other industries.