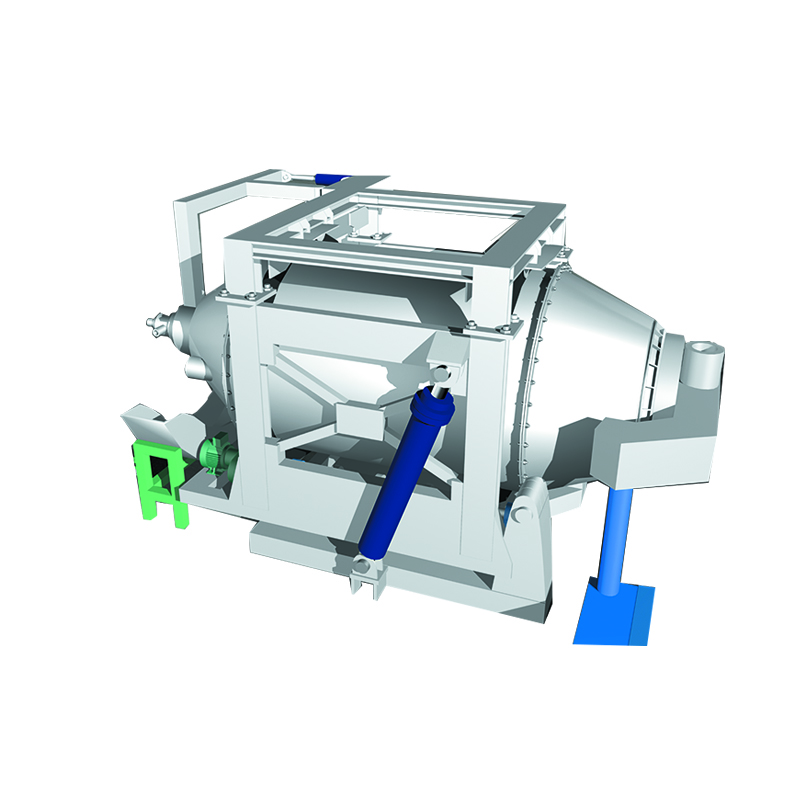

The process and production organization of the pure oxygen gas rotary furnace for melting cast iron are the same as those of the induction electric furnace. Its flexibility is very high. After the metal charge is added into the furnace at one time, the drum-shaped furnace body slowly rotates around its horizontal axis, and the solid metal is burned in the pure oxygen gas. It is melted into molten metal under the action of the mouth, and the molten iron is poured out before melting in the next heat.

Element burning loss rate: The burning loss rate of silicon, manganese and other elements in the pure oxygen gas recycling iron furnace is equivalent to that of the coke-burning cupola. Table 1 lists the general burning loss rates of carbon, silicon, and manganese for reference.

Element burning rate in rotary iron furnace | |||

alloy element | carbon | silicon | manganese |

Burning loss rate (mass fraction)/% | 20-25 | 25-30 | 30-35 |

Carburization of molten iron: The pure oxygen gas recirculation iron furnace is different from the coke-burning cupola. There is no process of carburizing the molten iron from the bottom coke. Therefore, the carbon content in the metal charge always shows a downward trend, and the mass fraction of carbon burned is between 20% and 25%. The carbon burned must be compensated by adding carburizing agents. The burning rate of carbon in the rotary iron furnace is affected by the following factors.

(1) The higher the carbon content in the charge, the higher the oxidation and burning loss rate of carbon;

(2) The smaller the capacity of the rotary iron furnace, the higher the oxidation burning loss rate of carbon;

(3) The shorter the smelting time, the lower the oxidation burning loss rate of carbon. The melting time is related to the rated power of the oxygen burner and its combustion control process. Using a larger power oxygen burner and paying attention to maintaining a larger flow of fuel supply will help reduce carbon burning loss.

When producing gray cast iron and ductile iron in a pure oxygen gas regenerative iron furnace, it is necessary to use a carburizing agent. Commonly used carburizing agents include: electrode graphite, calcined petroleum coke, and coke. Because of its high purity and high density, electrode graphite floats below the slag layer, can be in close contact with molten iron, easily dissolves into molten iron, and has the best carburization effect.

The above has analyzed the smelting characteristics of the rotary iron furnace from the perspective of burning loss rate and carbon increase. Next, it will also analyze the composition adjustment and inoculation treatment.