The rotary furnace has a wide range of uses and good results. It can smelt aluminum, aluminum ash, produce copper, aluminum alloy and other non-ferrous metals. When used with a pure oxygen burner, it can also smelt gray cast iron, cast steel and other alloys, as well as gray iron, ductile iron, etc. The process of iron melting in a pure oxygen gas rotary furnace is divided into the following processes: lining preheating → charging → charge preheating → charge softening → metal melting, slag covering → molten metal overheating → composition inspection and iron tapping → slag tapping.

Overheating of molten metal: After all the metal in the furnace is completely dissolved, the furnace body rotates in one direction at the highest speed, and at the same time, the burner heats the molten metal at maximum power to overheat the molten metal. Rotation of furnace body

Composition inspection and iron tapping: After confirming that the chemical composition of the molten iron meets the requirements of the casting, prepare the pouring ladle in time. When the taphole rotates to the lowest point, the furnace body stops rotating. Hang the pouring ladle under the taphole, use a steel drill and a hammer to open the taphole, and let the molten iron flow into the pouring ladle. The taphole is sometimes difficult to open, and you must always pre-open the taphole.

Prepare oxygen arc rods, thin steel pipes, oxygen, etc. When the tap hole cannot be opened with a steel drill, decisively use oxygen arc flame to blow open the tap hole.

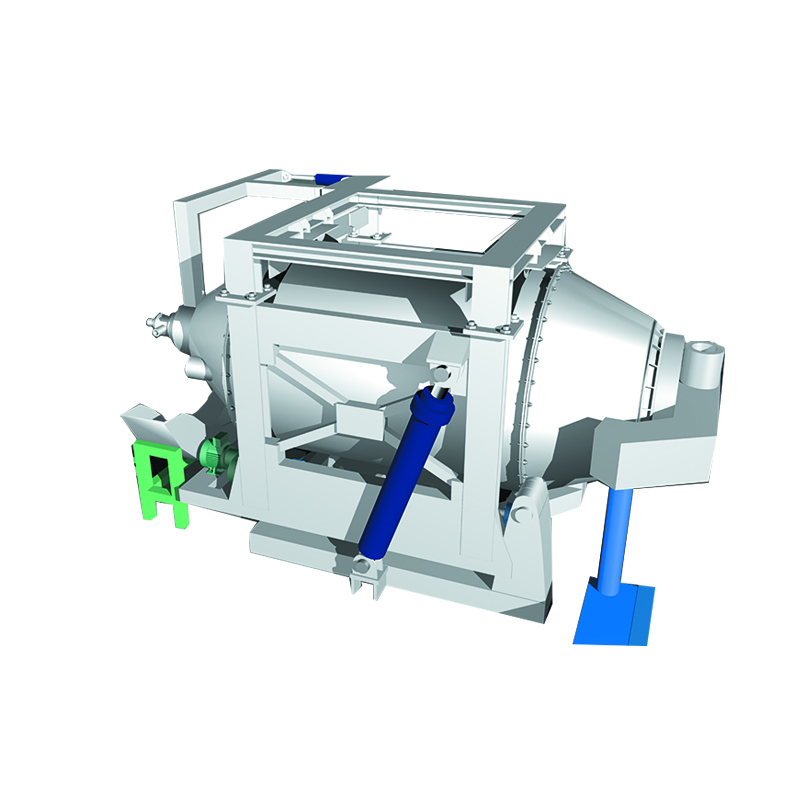

The capacity of the ladle used to tap iron from the rotary furnace should be larger than that of the rotary furnace. It is best to clean out the molten iron in the furnace at one time. If the ladle capacity is small, it may be necessary to repeatedly block and open the taphole, which is not conducive to improving the efficiency of the rotary furnace efficiency. Slag tapping: After tapping, first seal the tapping hole with refractory mud, and then use the hydraulic cylinder to tilt the furnace body 90° into a vertical state, and dump out the slag in the furnace at one time.

If the slag of the Pure oxygen molten iron rotary furnace is not dumped out at once and there is a large amount of slag remaining in the furnace, the furnace body can be leveled. After heating the furnace with a burner, tilt the furnace body 90° again and dump out the remaining slag in the furnace. of slag.